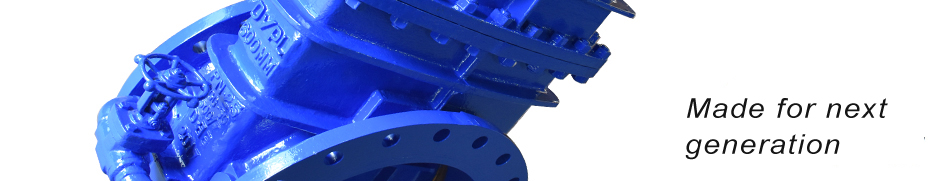

Plunger Valve

|

Plunger valves are designed for applications where precise flow control and pressure control are required, unlike butterfly or gate valves which are primarily for on/off functions.

A plunger valve, sometimes also called a needle or sleeve valve, works to precisely control and regulate water flow and pressure by using a cylindrical plunger that moves to open or close a flow path within a cylinder or valve body.

Mechanism: A cylindrical plunger, connected to a gear or actuator, is a cylinder that moves within the valve body. The movement of the plunger, controlled by the gear or actuator, controls the flow path, allowing for fine adjustment of flow rate and pressure.

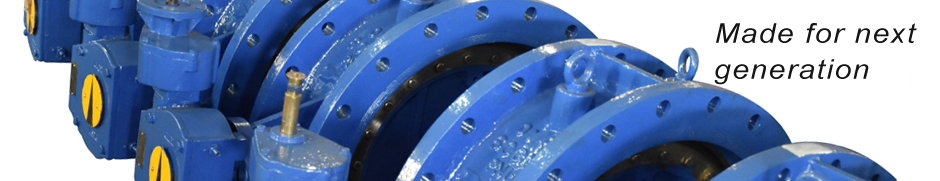

Application: Plunger valves are commonly used in water treatment plants, water distribution systems, and other applications where high flow rates and pressure control are required.

Advantages:

Precise flow control: Plunger valves provide better control over flow rates than some other types of valves.

High flow rates and pressures: They are designed to handle high flow rates and pressures, making them suitable for tough applications.

Self-cleaning design: Some plunger valves can be designed to be self-cleaning, which is beneficial in applications where there are suspended solids in the water.